Advancements in the aerospace industry are fueled by a convergence of technology, innovation, and precision engineering. The finite element method (FEM), a numerical technique for solving complex engineering problems, stands as a linchpin in the pursuit of progress. It allows engineers to dissect aerospace structures into smaller, more manageable elements, which enables an in-depth analysis of stress, strain, and deformation. This is one of the primary reasons why more and more working professionals enroll in FEM courses. FEM courses develop strong problem-solving skills.

While FEM finds extensive application in aerospace, its principles are versatile and applicable across various engineering disciplines. In this blog, we will delve into the pivotal role played by FEM in shaping the future of flight.

Top 5 Ways FEM Contributes to Advancements in the Aerospace Industry

Let us take a look at the top ways FEM contributes to aerospace industry advancements.

#1 Structural Resilience and Design Excellence

FEM plays a pivotal role in advancing aerospace engineering through its ability to analyze and optimize structures at a microscopic level. In the aerospace industry, where materials face extreme conditions, FEM enables engineers to dissect and scrutinize structures with precision. This microscopic analysis empowers the creation of lightweight yet robust designs, striking a delicate balance between strength and weight. Hence, by enrolling in a finite element method course, you will learn how to develop aerospace structures that can withstand the challenges of flight and ensure structural resilience and design excellence.

#2 Advancements in Material Science

At the forefront of material science innovation, the aerospace industry relies heavily on FEM to drive exploration and development. FEM plays a pivotal role in this endeavor by simulating the intricate behavior of novel materials across a spectrum of conditions. This simulation capability is particularly instrumental in crafting lightweight yet robust alloys and composite materials, which offer a gateway to groundbreaking possibilities.

#3 Enhanced Time & Cost Effectiveness

In contrast to traditional methods of prototyping and testing, which can be both time-consuming and financially burdensome, FEM emerges as a beacon of efficiency in the aerospace industry. Acting as a cost-effective virtual testing ground, FEM facilitates an accelerated product development cycle. Engineers can rapidly iterate through design variations and meticulously analyze performance under diverse scenarios, all without the need for physical prototypes.

Should you want to learn the finite element method, it is best to join an institute. They provide a wide range of FEM courses to help you learn about the latest tools and functionalities, making you well-prepared for the evolving demands of the industry.

#4 Propulsion Systems Perfected

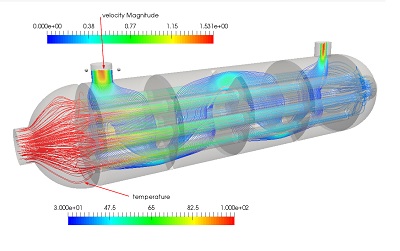

Propulsion systems are the heartbeat of aerospace engineering, demanding efficiency and power. FEM proves instrumental in simulating and optimizing the intricate components of jet engines and rocket propulsion systems. Through a detailed analysis of stress, heat, and vibration within these components, FEM empowers engineers to fine-tune designs for superior fuel efficiency, reliability, and overall performance. The contribution of FEM ensures that propulsion systems are perfected, meeting the dynamic and demanding requirements of the aerospace environment.

#5 Enhancing Crashworthiness for Safety

Safety is a non-negotiable aspect of aerospace engineering, and FEM plays a crucial role in enhancing crashworthiness. By enabling engineers to conduct meticulous crashworthiness simulations, FEM allows for a comprehensive examination of how various structural elements respond to impact forces. This capability contributes to the development of aerospace vehicles with enhanced safety features, which protect passengers and crew during unforeseen accidents or emergency scenarios.

Final Thoughts

The finite element method plays a crucial role in shaping advancements in the aerospace industry. From optimizing propulsion systems to enhancing crashworthiness, FEM is a cornerstone technology. Should you want to sign up for FEM courses, join Niharika Institute of Computational Engineering. We incorporate hands-on projects to allow students to apply FEM concepts to real-world engineering challenges.